CODESYS in FACTORY AUTOMATION

IEC 61131-3 Software Suite - perfectly suited for factory automation applications

CODESYS is used worldwide to automate serial and special machines for the production of a wide variety of goods. In the production of vehicle manufacturers and vehicle components, in additive manufacturing, in the furniture industry, in autonomous mobile robots (AMR) and in collaborative robotics - CODESYS can be found virtually everywhere.

Manufacturers are pursuing the goal of forcing higher productivity and cost efficiency and automation processes. CODESYS has every capacity to achieve just that. Top-tier manufacturing giants such as Bosch, Caterpillar and KUKA Robotics rely on CODESYS. The CODESYS Software suite helps set new standards in cutting-edge technology and develop innovative automation ideas to optimize all processes in manufacturing.

CODESYS plays a fundamental role when it comes to in-plant transport and material flow processes. Autonomous Mobile Robots (AMRs) and collaborative robotics are powered by CODESYS.

CODESYS is used in image processing-based and deep learning applications as well as in additive manufacturing and artificial intelligence in production, from intelligent production automation to warehousing and distribution.

ADVANTAGES

- CODESYS is a manufacturer-independent comprehensive and flexible system. All components for factory automation applications are integrated directly in CODESYS, including editors for all IEC 61131-3 compliant implementation languages (6), compilers for native machine codes, a powerful debugger, and a clear project configuration. Add-ons can further supplement these components for efficient application development.

- CODESYS real-time is characterized by a predictable (deterministic) time behavior of a microseconds jitter. If a real-time system sets the task (by configuration) to execute certain routines within a predefined time frame, in CODESYS this happens down to a hundred microseconds cycle time.

- Many tasks in the factory automation like the fieldbus configuration, the creation of modern visualization screens for machine operation, planning and execution of complex motion control, CNC and robotic movements, implementation of safety applications to DIN IEC 61508 SIL3 and others are integrated in CODESYS.

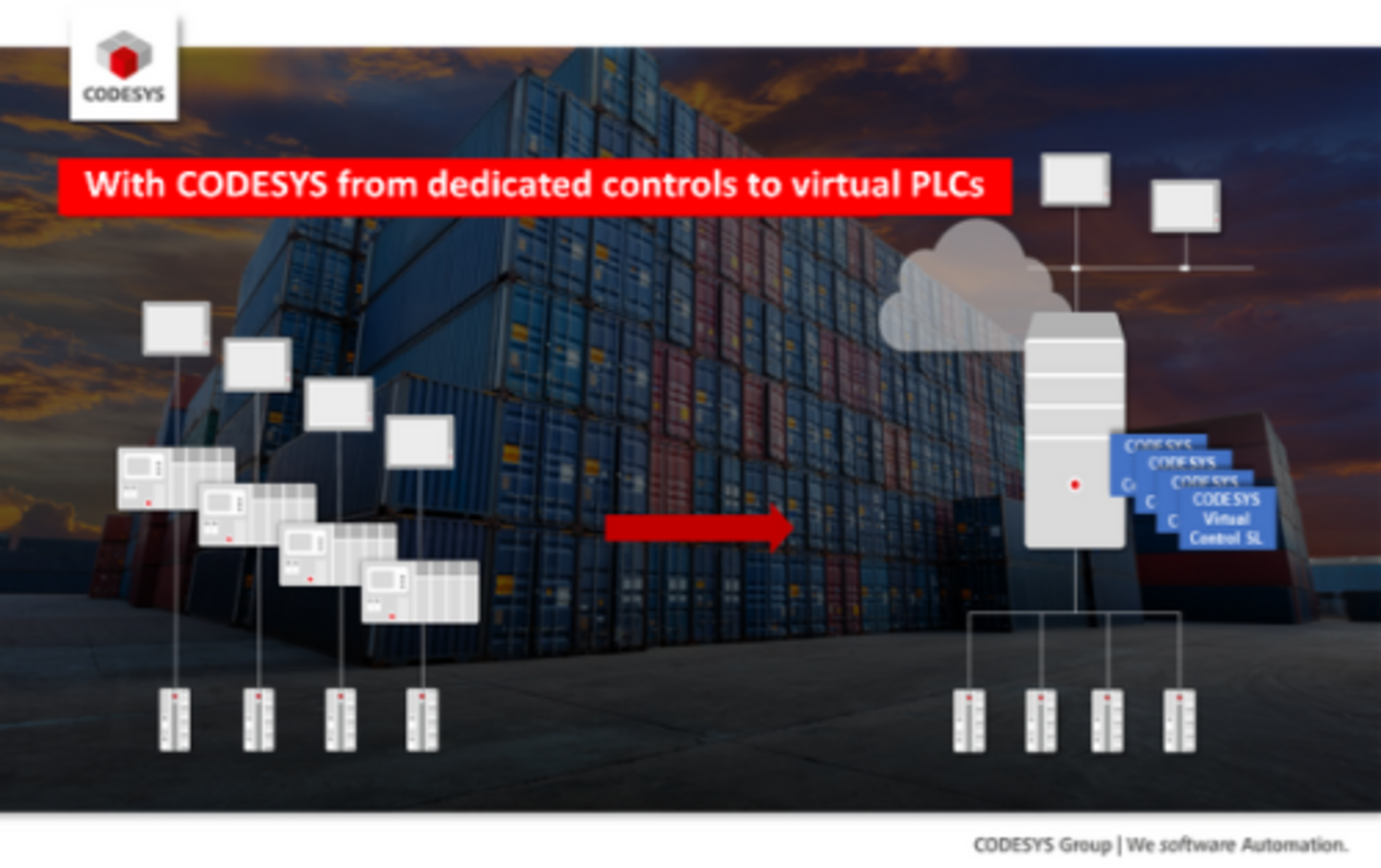

- CODESYS is used in over 1,000 different controllers around the world.

- For efficient developments and diagnostics CODESYS has integrated analysis tests, simulations, and offline tests.

- CODESYS includes efficient configuration, commissioning, and debugging tools to assist factory automation engineers throughout the development of their projects.

- The option to use Object Oriented Programming (OOP) designs facilitates modular and highly reusable code for control applications and significantly reduce development and maintenance time.

- The CODESYS TargetVisu is ideally suited for the operation and maintenance of factory machines directly on the controller.

- The integrated safety (DIN IEC 61508) and redundancy functions in CODESYS are ideal for high availability and safety-critical applications.

- Engineers are provided with extensive runtime diagnostics information and can safely update the application without stopping it - securely from all over the world.

- CODESYS is used in applications for compact IP67 controllers in rough environments.

- CODESYS supports important communication protocols such as OPC UA, MQTT, ETHERNET-IP, PROFINET or Modbus with integrated configuration tools.

CODESYS FACTORY AUTOMATION BROCHURE

CODESYS in the AUTOMOTIVE INDUSTRY

One single Software Suite for all automation production processes

AUTOMATION POWERED BY CODESYS

CODESYS Software Suite - perfectly suited for every industry