CODESYS VIRTUAL PLC

The latest evolution of Industrial Automation 5.0

CODESYS Virtual Control has no hardware requirements

CODESYS has been offering hardware-independent Soft PLCs for over 20 years and continuously they have been expanding their products. Today, CODESYS provides hardware-independent Soft PLCs with and without real-time for Windows, as well as Soft PLC solutions for Linux x86 and ARM-based systems.

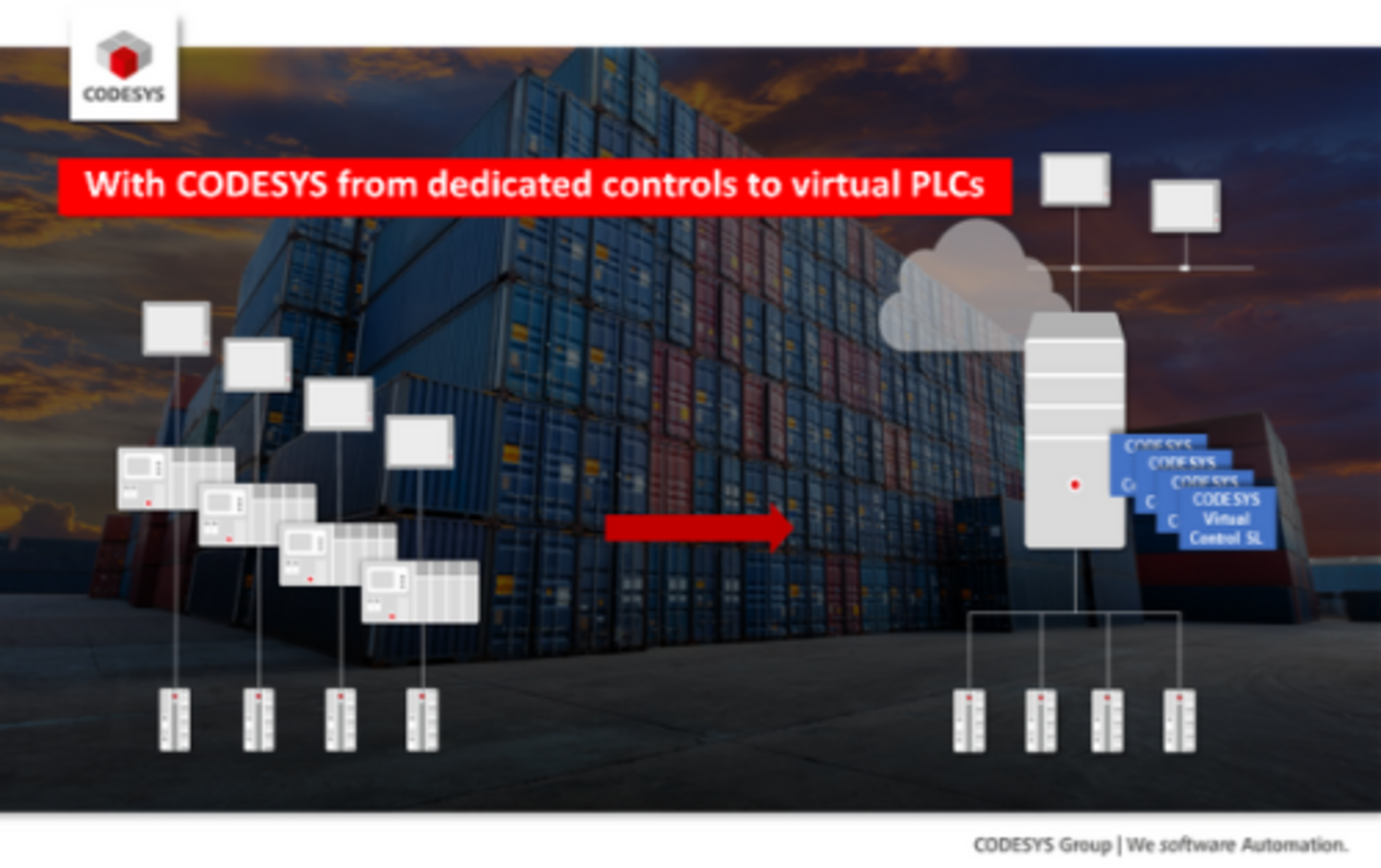

The CODESYS Virtual Control is a more advanced product towards the future. It allows the CODESYS Soft PLC to run in a virtual environment without the need for a device. Instead, the device gets replaced by containers and hypervisor technologies.

The CODESYS Virtual PLC can be installed multiple times on a device and has no hardware requirements. It is connected to the Automation World via virtual LAN. CODESYS Virtual Control SL is available for purchase in the CODESYS North America Store.

CODESYS device manufacturers can offer their customers images / configurations for CODESYS Virtual Control SL on their computers and industrial devices. This gives customers and users of automation systems maximum freedom in the development of control applications, which they can then organize in separate "micro-services", for example.

To deploy or orchestrate CODESYS Virtual Control SL, CODESYS users can choose any computer architecture, such as industrial devices, servers or cloud platforms. In this way, exactly those virtual controllers required for the application can be implemented.

Performance can also be precisely scaled. All control instances can be orchestrated via Linux commands or scripts, with appropriate tools (e.g. Kubernetes, Open Shift) or directly from the CODESYS Automation Server. Access to the field level is via a powerful virtual LAN, which is also available in all industrial devices.

ADVANTAGES

- A significant reduction in costs and effort for procurement,

- wiring,

- maintenance,

- rolling out applications and device administration.

- The control cabinet is no longer occupied by one or more controls.

- Power supply units and their wiring are no longer necessary.

- Easy scaling through dynamic creation of control instances and the ability to expand hardware independently from software.

- Security by design by distributing tasks to several independent control instances with powerful intercommunication.

- Interoperability with other services ("micro services")

- OT and IT merge completely

Instead of procuring and installing several controllers, it is sufficient to load an available IT platform in the network with virtual controllers and to manage them centrally - performed by IT specialists instead of automation specialists.

CODESYS VIRTUAL CONTROL SL INSTALLATION

Discover CODESYS Virtual Control SL in the CODESYS North America Store or obtain it directly via the CODESYS Installer.

The download from the CODESYS Store provides you with the complete CODESYS package. Simply install it in the CODESYS Installer interface or directly by double-clicking.

The package contains all the necessary components to put your virtual controllers into operation.

You will find further information in the CODESYS Online Help.

CODESYS VIRTUAL SAFE CONTROL

With CODESYS Virtual Safe Control, any containerized platform can be used as a safety controller - including safety certification.

The software solution creates dual-channel capability through "Diversified Encoding", which is based on "Coded Processing". The processing of the application is divided into two logical software channels:

- The first channel simply executes the implemented safety application as is.

- The second channel uses the same application, but executes it with the algorithms of "coded processing" and can therefore already detect errors.

Both channels run on a virtual PLC in a process sequentially one after the other on a CPU core. They constantly check each other. Diversified Encoding distributes the safe inputs to both channels and, conversely, combines the outputs of both channels into safe outputs. This includes data streams that are generated by safe network or fieldbus protocols. The safety concept of SIListra Systems GmbH has been approved by TÜV SÜD.

The release and certification of CODESYS Virtual Safe Control as a hardware-independent solution is planned for the first half of 2024. As before, the safety application can be configured in the safe IEC 61131-3 editor as part of the certified add-on module, which extends the purely functional part of the CODESYS Development System. The user only notices that these are virtualized devices when connecting the safety I/O modules in the application.

Setup and Measurements from a Live Demo – see here

CODESYS VIRTUAL PLC BROCHURE and VIDEO

CODESYS Virtual PLC

Automation powered by CODESYS - The next industrial evolution:

CODESYS Virtual PLC

AUTOMATION POWERED BY CODESYS

CODESYS Software Suite - perfectly suited for every industry

CODESYS CONTROL SL INSTALLATION VIDEO

How to install CODESYS Control SL

CODESYS CONTROL SL VIDEO

CODESYS sets new standards - CODESYS Virtual PLC